Leading Edge Projects

Leading Edge Projects

- Home

- Leading Edge Projects

We work everyday to develop and test VR and AR immersive solutions, taking part to leading edge projects to strengthen and improve our skills and competences.

By using hardware proprietary applications, we experiment and achieve new standards in visualization, with the goal to improve user’s immersive experiences.

We are particularly committed to enhance growing intuitive interactions between users and software as to implement the new achievements in our patented platform.

DISLO-MAN - Dynamic Integrated ShopfLoor Operation MANagement for Industry 4.0

The DISLO-MAN platform aims to integrate the manufacturing systems with the sensor network tools present on machines and equipment, to continuously detect production parameters to optimize the manufacturing flow and minimize non productive moments. The project will also realize effective predictive models for real-time analysis is based on a combination of statistical methods, Big Data Analytics techniques, Machine Learning, and rule-based semantic reasoning. Go to project...

XR³ FOR MOLDING

The objective of the XR³ project is to evolve and integrate the actual VR-STAR platform, an immersive 3D training system in virtual reality, with new features for the the molding industry:

- a combination and integration between Virtual reality and Augmented Reality to provide support through mobile devices that are able to display operating procedures, charts, level gauges and other information about the actual status of the machines as well as the virtual representation of the framed machine

- an advanced fluid-dynamic simulation software for identifying best molding parameters

- an experiential database, which is updated automatically and continuously

- an immersive simulator in virtual reality that reproduces the molding process

A4BLUE - Adaptive Automation in Assembly For BLUE collar workers satisfaction in Evolvable context

A4BLUE proposes the development and evaluation of a new generation of sustainable, adaptive workplaces dealing with evolving requirements of manufacturing processes, the introduction of automation mechanisms that are suitable for flexible and efficient task execution in interaction with human workers and by optimising human variability through personalised and context aware assistance capabilities as well as advanced human-machine interfaces. In the project Illogic is in charge of the VR/AR based training and guidance tools to be used for simulation and training of the different tasks in assembly, inspection or maintenance procedures as well as support tools for the real time completion of these tasks Go to project...

VASARI

VASARI builds a new cultural space in which the physical spaces of museums and historical sites with their patrimony of works are integrated into the digital space of Cultural and interconnected content and services in a multi-site logic. The visitor and the works are at the center of this space where knowledge, enjoyment and participation of citizens and tourists is encouraged, while the management, the enhancement and the cooperation of cultural institutions is facilitated.

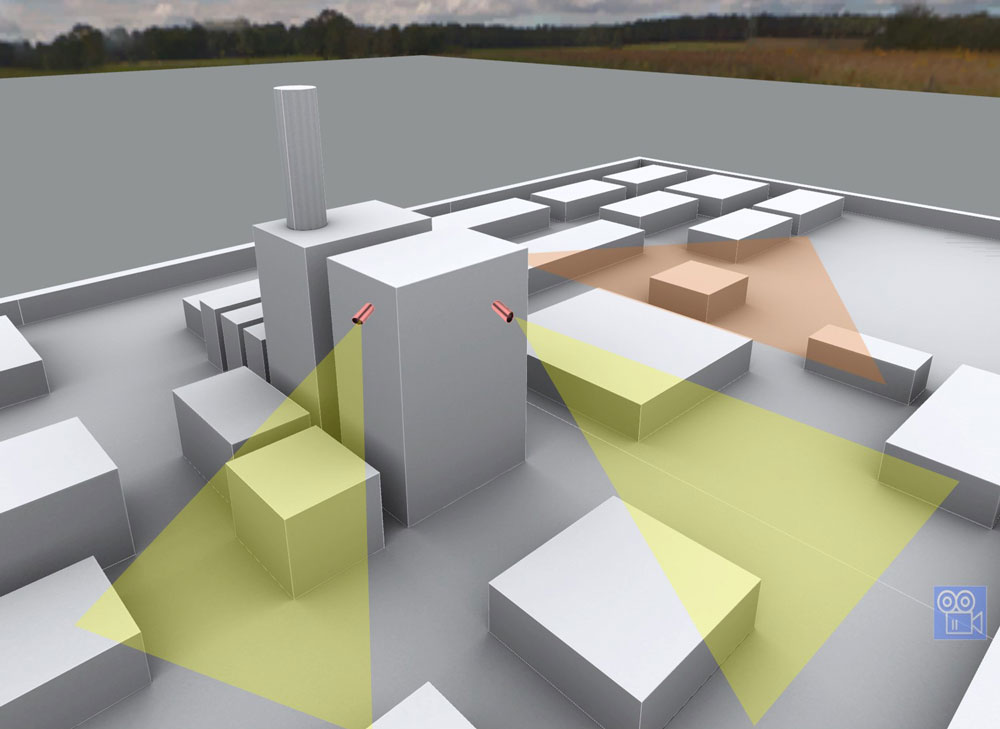

Visiongear

Using new digital technologies such as augmented and virtual reality, Visiongear allows the Operator to access all the information he needs while operating in the field and receive real time support by Subject Matters Experts located remotely. Always connected, field operators can receive and visualize instructions on dedicated devices (wearable) and can execute tasks (with free hands) more effectively and efficiently. Go to project...