XR-STAR | VR Platform

Products Virtual Reality Virtual Prototype

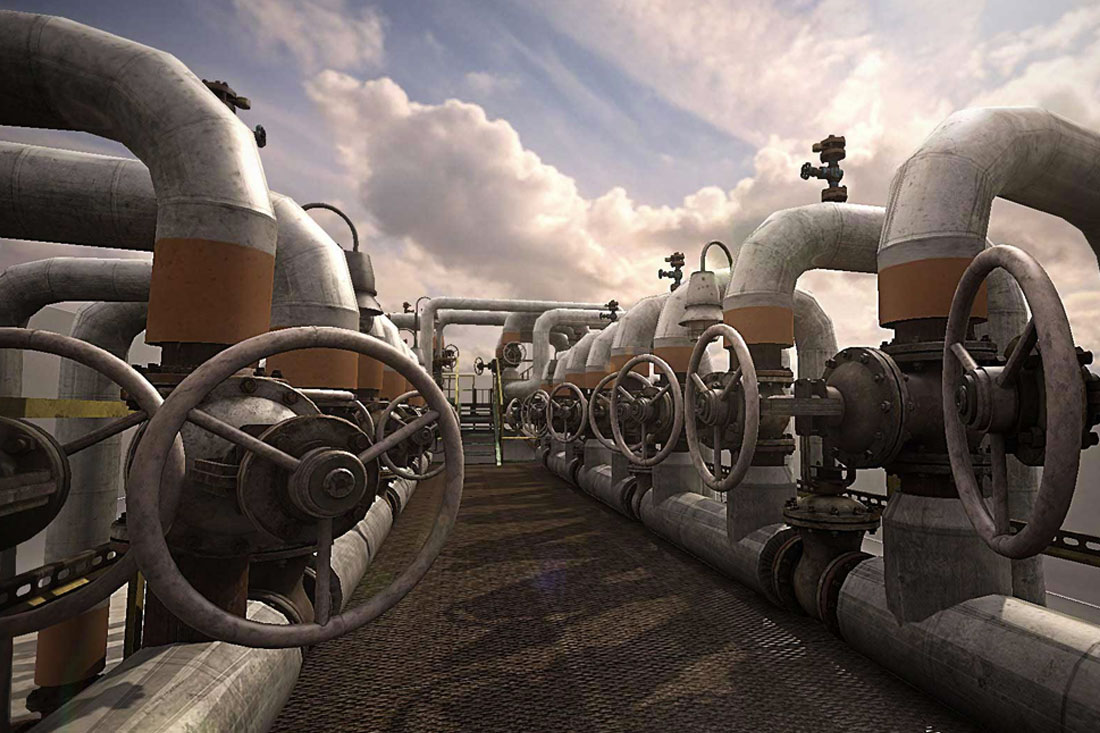

XR-STAR® is the most complete Virtual Reality software platform for the Oil&Gas Industry available today. It represents a new generation of Operation Training Solutions (OTS) based on immersive stereoscopic 3D Virtual Reality technologies.

XR-STAR® platform can be used in all these contexts:

- Pre-visualization for construction

- Training of human resources improving efficacy and efficiency of training final results

- Operational Management by simulating processes

- Risk Management by improving HSE (Health Safety Environment) policies for preventing human accident

Immersive training is crucial to increase Plant safety: traditional training simulators do not cover field operators.

XR-STAR® uses the best available technologies to create the photo-realistic version of a plant (or unit) and equipment by creating a 3D virtual immersive hyper-realistic environment. In this way, operators can train, interact and practice as they were in the real plant with the real equipment.

XR-STAR ADVANTAGES

XR-STAR® platform can give your organization a lot of advantages:

- Enhance the EFFECTIVENESS OF TRAINING and knowledge transfer through learning by doing, interaction and participation

- Optimize TRANSFER OF KNOWLEDGE and skills from “off-line” training environments to the real work environment (e.g. animation of functioning of equipment provide better training results since it is interactive and visual)

- Provide PERFORMANCE EVALUATIONS for trainers and trainees

- Create RISK FREE ENVIRONMENTS to practice, test and develop competences, by simulating situations that cannot always be reproduced in reality (risky situations, incidents, emergency shutdowns, etc.). Operators can thus practice on procedures, improve their skills for rarely-performed but safety-critical tasks and learn how to quickly and correctly react in high stress situations.

- Accelerate COST SAVING

- time and cost savings of 30% to 40% originate from on-the-job training for new large personnel requirements, considering downtime savings and replication of training programs from plant to plant

Trainers and trainees can be located throughout the world and using web facilities, remote workers can work together in the same virtual area, on a chemical plant or a building site, resulting in a reduction in travel time and expense. In addition, interactive training preserves the plant’s best practices and the enterprise replaces the aging workforce; - Start-up efficiency savings of 15% to 25% time reduction originate in “back-on-run” situations from planned or unplanned shutdown, by using VR interactive training to quickly and frequently refresh all plant crew on all their critical procedures;

- maintenance savings of 1% to 3% can be achieved by improving maintenance operator accuracy and performance, and by using data from the training experience as input to improve predictive maintenance strategies.

- time and cost savings of 30% to 40% originate from on-the-job training for new large personnel requirements, considering downtime savings and replication of training programs from plant to plant

MODULES

XR-STAR® is a modular platform and offers you:

- XR-STAR Tutorial Training Version: the platform is tutorial based and allows trainee to learn strategic operative steps and assess performances

- XR-STAR Event Driven Version: training events are driven by the “Instructor Station” module from where the trainer monitors how trainees behave and react in real time to simulated situations